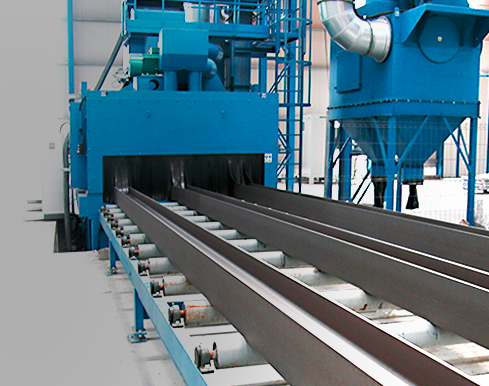

Indabrator is an ideal service provider in the engineering segment. The company believes in a single-window solution for all surface-preparation needs. This includes machines, spares and abrasives. Indabrator's leadership is defined by its total immersion across the value chain with its own foundry and state-of-the-art manufacturing unit.

The company's pioneer 'Wheelblast' technology offers standard as well as highly customised design. The 'Airblast' technology with Room Plant provides solutions for batch as well as continuous production requirements.

The company’s comprehensive range of fabric filters are suitable for both low and high temperature operations.

They control overspray and treat in a manner whereby any excess overspray can be thoughtfully disposed of outside the building. This is a method that considerably reduces chances of hazard and keeps the fire risk to a minimum in the spray shop.

The brand maintains a large inventory of replacement and spare parts at locations across India for consistent availability and immediate dispatch.

The double heat treatment, coupled with quality control measures ensures a shot that stays round throughout its life-cycle.

The O&M solution also manages inventories, trains personnel and initiates preventive maintenance programs.

As OEMs, Indabrator keeps customer equipment running continuously and in good condition. The AMC also extends to shot-blasting machines of any brand in the customer's arsenal.

sq. ft. of

manufacturing

capacity

customised

installations

years of

experience